Sehgal Exports manufactures Innovative & Precision-engineered Range of Chapati Making Machines. We have 3 machines installed in our Industry which saves our lot of time daily. We are total satisfied with their services.

We manufacture high quality Fully Automatic Chapati making machines, Biscuit Mouldings and Rotary Cutting Rollers.

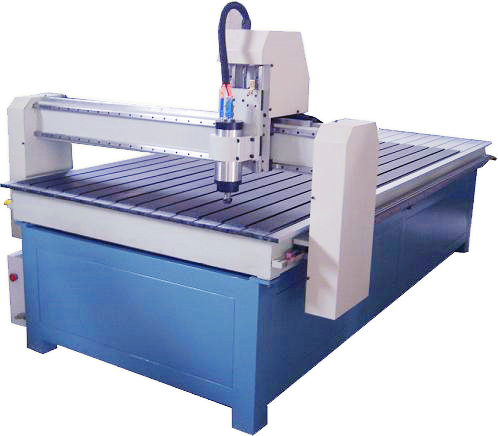

We make use of latest machinery for manufacturing our products. we keep on upgrade our manufacturing unit every now and then with new machines and techniques.

Our Chapati machines are applicable for Business Use, Hotel/Restaurants, canteen/Mess etc. Our Biscuit Die rollers are main tool for Biscuit Die Industry.

All production is performed by qualified professionals and skilled engineers and labour to help them. Our personnel are also given advanced training to handle the new machines.

CHAPATI MAKING MACHINE

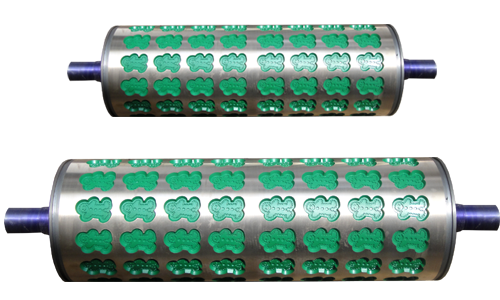

BISCUIT DIE ROLLERS

We offer an environment friendly, easy to use and defect free range of food processing machinery which is fabricated using superior quality raw material. Our all encompassing range includes Food Making Machinery such as Automatic Chapati Making Machine, Kitchenware, Biscuit Plant Machine, sandwich machine and papad making machine.

We offer an environment friendly, easy to use and defect free range of food processing machinery which is fabricated using superior quality raw material. Our all encompassing range includes Food Making Machinery such as Automatic Chapati Making Machine, Kitchenware, Biscuit Plant Machine, sandwich machine and papad making machine.

We have maintenance free chapati making machines of every capacity, ranging from 1000 to 40,000 chapatis in one hour. Easy to install, easy to use, easy to clean and very economical. Machine operates with only 1 hp motor and is very compact in size. Our machines are applicable for Business Use, Hotel/Restaurants, canteen/Mess etc. Read More

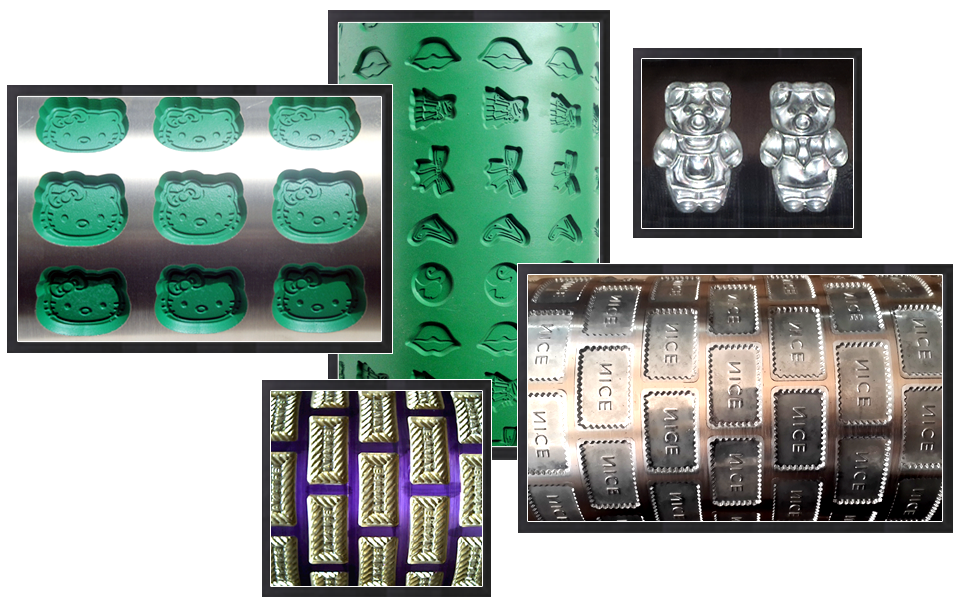

We are a renowned company since 1993 engaged in the manufacture, export and supply of a technologically advanced range of accurately engineered Biscuit Molds and Cutting Die Rollers, which are exclusively made to produce soft dough and hard dough biscuits of different kind and taste as per the requirement. We use latest German Technology CNC Machine and Cad Software to make Special Insert Die Molds. We have ourown foundry shop to produce Gun Metal Castings. Every Process is in house thus leading to better quality and on-time delivery..

We are a renowned company since 1993 engaged in the manufacture, export and supply of a technologically advanced range of accurately engineered Biscuit Molds and Cutting Die Rollers, which are exclusively made to produce soft dough and hard dough biscuits of different kind and taste as per the requirement. We use latest German Technology CNC Machine and Cad Software to make Special Insert Die Molds. We have ourown foundry shop to produce Gun Metal Castings. Every Process is in house thus leading to better quality and on-time delivery..

The quality process starts with the procurement of high grade raw materials which are quality checked at ourfacility before using them further in production. Moreover, every step ofmanufacturing is strictly scrutinized by our quality engineers. Every production process conforms with international quality standards and procedures.

We have a modern manufacturing facility that is planned out in way that enhances production and efficiency. Our facility is fully geared with latest tools and equipment. Our production line is well supported by separate yet integrated design, quality and research and development units. Read More...